A Probably Breakthrough in Integrated Water Treatment with Less Land Use and Less Investment:The Oxygen-limited RPIR Technology

The oxygen-limited RPIR technology represents a breakthrough in integrated water treatment. It's particularly effective for concentrated organic wastewater. This space-saving sewage treatment plant is not only cost-effective but also straightforward in terms of operation and maintenance. When it comes to organic wastewater, especially high organic and concentrated organic wastewater, RPIR technology is truly a game-changer.

Integrated wastewater treatment is a crucial aspect of modern environmental technology profiles. Finding the right wastewater treatment solution is essential for maintaining environmental health and sustainability. Industrial wastewater often contains high levels of ammonia nitrogen, and effective treatment technology is necessary to manage this type of pollution.

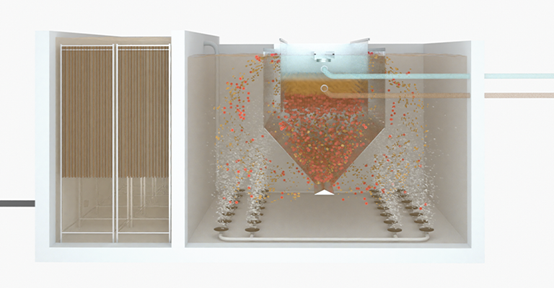

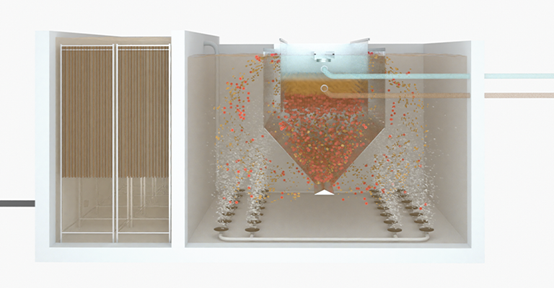

The oxygen-limited RPIR technology is derived from the RPIR technology independently developed by Qingyan Environment, and is combined with the most efficient biological denitrification process anaerobic ammonia oxidation technology. The oxygen-limited RPIR is an integrated short-range nitrification-anaerobic ammonia oxidation-precipitation separation reactor, which organically combines the four functions of aeration oxygen supply, airlift circulation, short-range nitrification-anaerobic ammonia oxidation biochemical reaction, and precipitation separation. Through the sludge age control system and precise aeration control system, a stable and intensive high-efficiency biological denitrification sewage treatment reactor is formed.

Low operating cost, less pretreatment dosage, and greatly reduced core section aeration energy consumption. Small footprint, high biochemical unit load, short residence time. Low sludge production. Simple operation and maintenance, no sludge external return system, and zero added carbon source. Oxygen-limited RPIR high-ammonia nitrogen wastewater treatment system. The oxygen-limited RPIR technology combines functional microbial flora containing high-concentration red bacteria, oxygen-limited RPIR separation module, and intelligent control system to build an efficient, reliable, stable, replicable, modular, and standardized anaerobic ammonia oxidation engineering product.

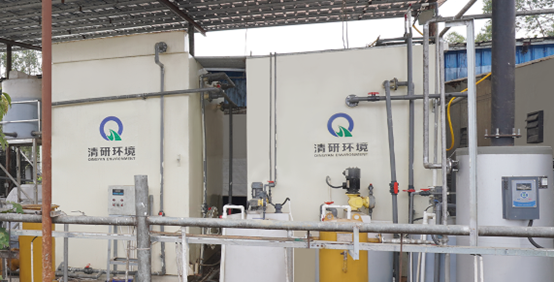

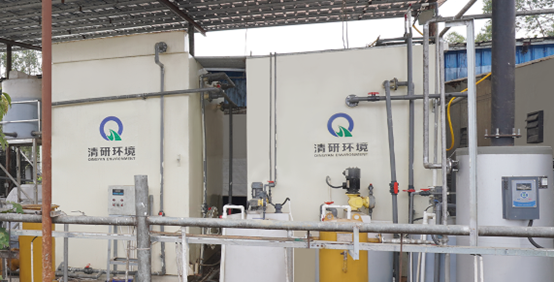

Huizhou Black Soldier Fly Breeding Base Food Waste Leachate Treatment Project. Treatment scale- ten cubic meters per day. Effluent standard- Pipe standard. Process flow- pretreatment, anaerobic RPIR, A/oxygen-limited RPIR, and RPIR. Project highlights- Compared with conventional processes, this process- Pretreatment drug consumption is reduced by eighty percent, and energy consumption is reduced by forty percent. The overall residence time is shortened by thirty percent, and the operating cost is reduced by fifty percent.

Shenzhen Longgang District Yunan Environmental Park Biogas Treatment Project. Processing scale- twenty cubic meters per day. Effluent standard- Pipeline standard. Process flow- A/O, limited oxygen RPIR, and A/RPIR. Project highlights- No need to add carbon source, aeration energy consumption is reduced by sixty percent, and operating costs are reduced by forty percent. Compared with traditional processes, the overall hydraulic retention time is reduced by sixty percent. Integrated equipment is used, and project construction is fast. Intelligent control system is used to ensure stable effluent and meet standards.

LOADING...

LOADING...

DATE:2024年08月12日

DATE:2024年08月12日