Application of Oxygen-limited RPIR Technology for High-ammonia Nitrogen Wastewater Treatment Based on Anaerobic Ammonium Oxidation in the Biogas Slurry Treatment Project in Yunan Environmental Park, Longgang District, Shenzhen

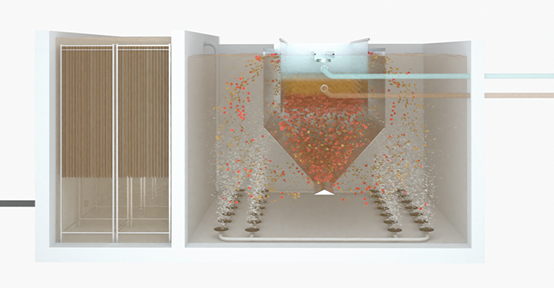

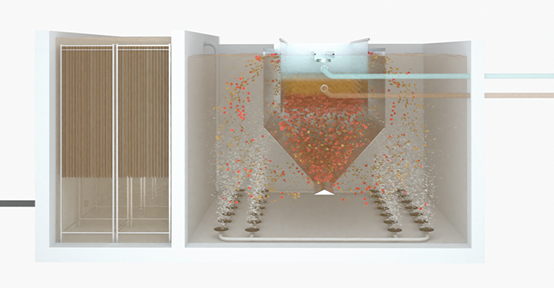

Hey everyone! Ever wondered how Shenzhen is addressing its wastewater challenges? Let me take you on a quick journey through the innovative Shenzhen Yunan Park Biogas Treatment Project. So, what makes this project so special? First off, it’s all about RPIR technology. RPIR stands for Reactor with Partial Internal Recycling. It’s a mouthful, I know! But this tech is revolutionizing the way we treat high-organic wastewater. Essentially, it integrates multiple processes to treat concentrated organic wastewater efficiently. The Yunan Park project is a game-changer with its A/O + limited oxygen RPIR + A/RPIR process flow. In simple terms, this means it combines anaerobic and aerobic processes with limited oxygen RPIR technology. This setup treats wastewater to meet pipeline discharge standards, specifically GBT 31962-2015. Pretty impressive, right? Let’s dive into the project highlights!

First, there’s no need to add any carbon source. This reduces aeration energy consumption by a whopping 60%! And, guess what? Operating costs go down by 40%! That’s a huge win for both the environment and the budget. Next, compared to traditional processes, the overall hydraulic retention time is cut by 60%. This means the water spends less time in the system, making the process faster and more efficient. And who doesn’t love saving time? The project uses integrated equipment, which means it’s space-saving and quick to construct. Imagine having a fully operational sewage treatment plant set up in no time! That’s the power of integration. But the cherry on top? The intelligent control system. This ensures the effluent is stable and consistent, meeting all required standards without a hitch. It’s like having a smart assistant making sure everything runs smoothly. So, why is this important? Well, treating high-ammonia nitrogen wastewater effectively is crucial. Traditional methods can be costly and time-consuming. But with the Shenzhen Yunan Park approach, we’re looking at a cost-effective, efficient, and simple operation and maintenance solution. In essence, integrated wastewater treatment is the future! With technologies like RPIR and processes like anaerobic ammonium oxidation, we’re making significant strides in environmental technology. Shenzhen Yunan Park is leading the way. To all the engineers out there, keep an eye on these advancements. They could very well be the blueprint for future wastewater treatment solutions worldwide.

Anaerobic ammonium oxidation, or Anammox, is a key player in this project. This process is highly efficient in removing ammonia nitrogen from wastewater. One of the standout features of Anammox is its low energy consumption. It significantly reduces operating costs, making it a budget-friendly option. Plus, there’s no need to add any carbon source, which simplifies the process. The Anammox process also has a small footprint, making it ideal for urban areas. This technology is a game-changer in the field of wastewater treatment. It’s paving the way for future wastewater treatment solutions worldwide. If you found this video insightful, don’t forget to like and subscribe. Stay tuned for more on cutting-edge environmental technologies. See you next time!

LOADING...

LOADING...

DATE:2024年07月30日

DATE:2024年07月30日