Qingyan Environmental has developed a set of process technology and equipment suitable for high-concentration organic wastewater such as kitchen waste leachate, livestock and poultry breeding wastewater, and landfill leachate, which have the characteristics of small water volume, high pollutant concentration, high solid and oil content, etc. The technology ensures that the effluent reaches the sewage discharge standard (GBT31962-2015) for urban sewage, and effectively solves the problems of large land area occupied by existing treatment processes, low degree of equipment integration, unstable process operation, and difficult stable compliance with standards.

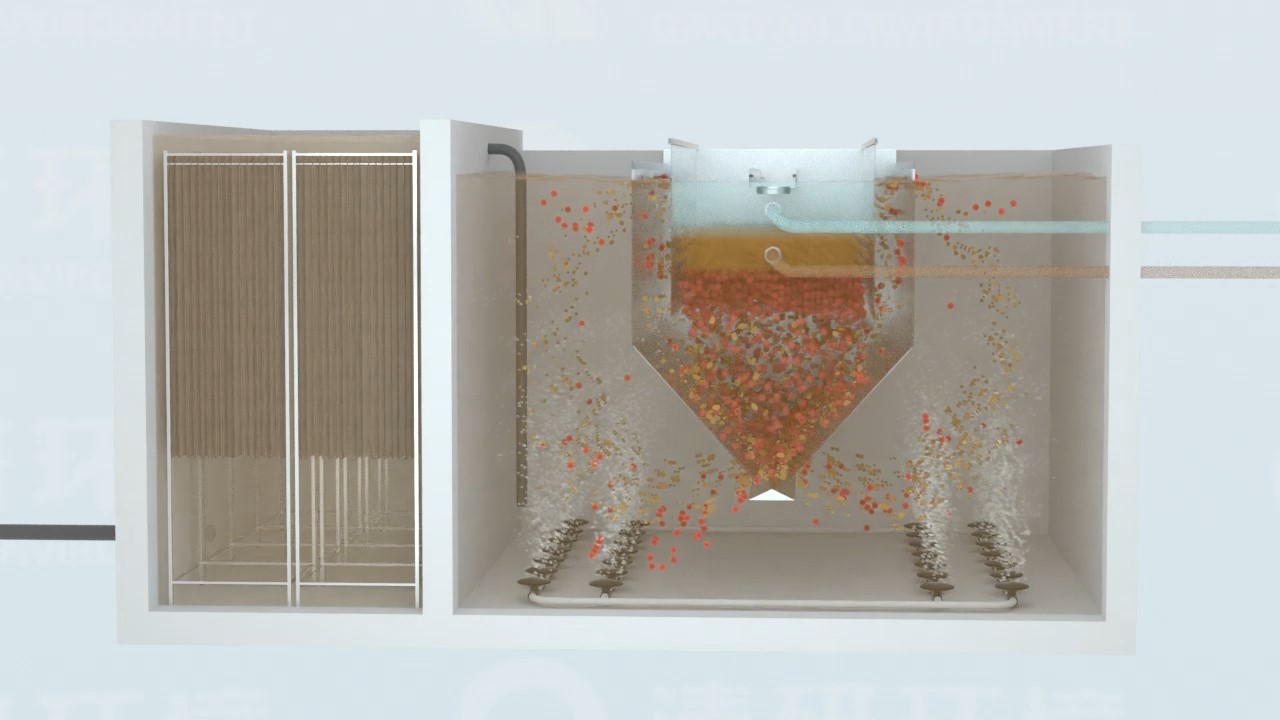

Oxygen limited RPIR all-in-one machine

The limited oxygen RPIR uses aeration power to generate loop and internal circulation, enhances mass transfer, and reduces aeration energy consumption by using the partial nitrifcation and anaerobic ammonia oxidation process to achieve efficient removal of total nitrogen. The reaction and sedimentation vertically couple and trap high-concentration sludge, saving land. There is no need for sludge and nitrification liquid reflux, further reducing power consumption.

Anaerobic RPIR all-in-one machine

The anaerobic RPIR combines the advantages of UASB and RPIR, and can use the biogas airlift power to generate loop and internal circulation so as to enhance mass transfer, thus saving power consumption. The anaerobic RPIR integrated equipment is high in integration level, high in volume loading, less in land occupancy, low in energy consumption and capable of energy production.

Qingyan Environmental Technology Co., Ltd.

Qingyan Environmental Technology Co., Ltd.

Contact Number

Contact Number WeChat Service

WeChat Service

Follow Us

Follow Us