Rapid Purification of sewage using sedimentation Integrated rectangular airlift loop Reactor (RPIR) is an international advanced rapid biochemical wastewater treatment technology independently developed by Qingyan Environmental.

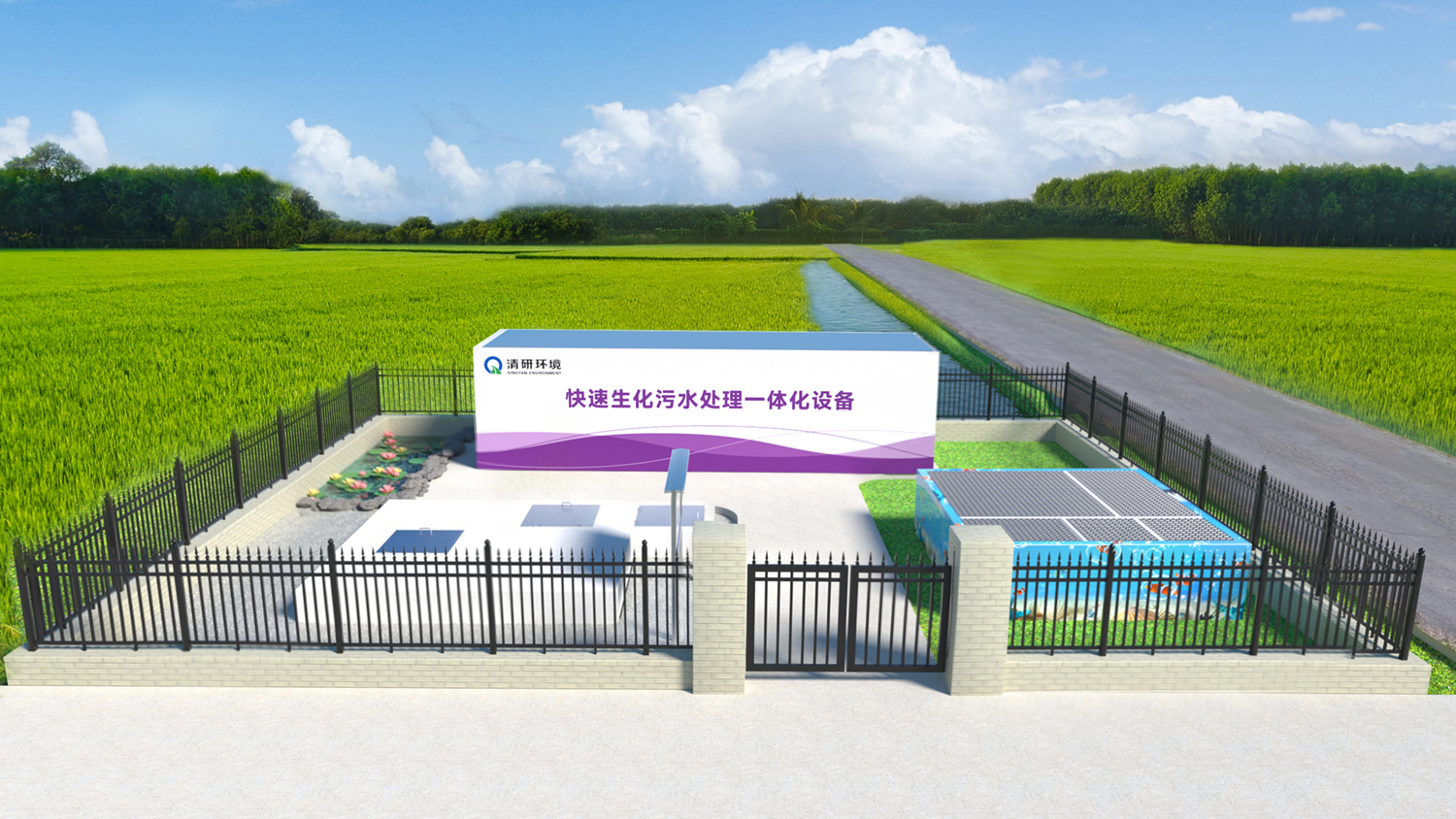

RPIR rapid biochemical sewage treatment process organically couples the four functions - aeration for oxygen supply, airlift loop, biochemical reaction and separation by sedimentation together to form an intensive and efficient biological sewage treatment reactor, which does not require sludge return, thus shortening the process flow of sewage treatment. The core equipment of the technology is the RPIR standard module, which has a unique structural form, either assembled combination equipment or skid-mounted sewage treatment all-in-one machine.

RPIR rapid biochemical sewage treatment process organically couples the four functions - aeration for oxygen supply, airlift loop, biochemical reaction and separation by sedimentation together to form an intensive and efficient biological sewage treatment reactor, which does not require sludge return, thus shortening the process flow of sewage treatment. The core equipment of the technology is the RPIR standard module, which has a unique structural form, either assembled combination equipment or skid-mounted sewage treatment all-in-one machine.

Qingyan Environmental Technology Co., Ltd.

Qingyan Environmental Technology Co., Ltd.

Contact Number

Contact Number WeChat Service

WeChat Service

Follow Us

Follow Us