Application of oxygen-limited RPIR technology for high ammonia nitrogen wastewater treatment with zero carbon source addition in the leachate treatment project of restaurant kitchen waste in the black soldier fly breeding base in Huizhou

The Huizhou Black Soldier Fly Breeding Base Food Waste Leachate Treatment Project is a good project of modern engineering. It’s a large-scale operation, capable of treating vast amounts of food waste leachate every day. This leachate, a liquid produced as food waste breaks down, is highly polluting. The project aims to treat this leachate to a high standard. This standard ensures the treated water is safe for the environment. The project’s success sets a new benchmark for sustainable waste management. It demonstrates the power of innovation and collaboration.

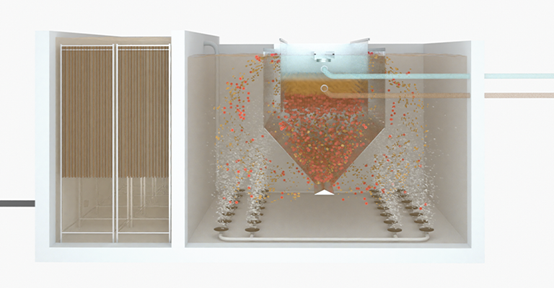

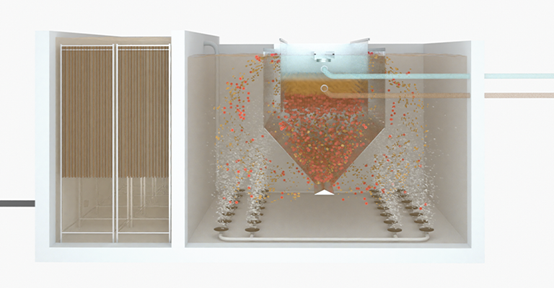

The Huizhou project utilizes a multi-stage treatment process. This process ensures the complete breakdown of pollutants in the food waste leachate. The first stage involves pretreatment. Here, larger solids are removed from the leachate. Next, the leachate enters the anaerobic RPIR stage. This stage utilizes specialized bacteria. These bacteria break down organic matter in the absence of oxygen. The real innovation lies in the next stage - the A/oxygen-limited RPIR. Developed by Qingyan Environment, this process optimizes the breakdown of pollutants. It does so by carefully controlling the oxygen levels. Finally, the treated water undergoes a final RPIR stage. This stage polishes the water, removing any remaining contaminants. The result is clean water that meets stringent environmental standards.

The A/oxygen-limited RPIR technology offers significant advantages. It reduces the need for expensive chemicals typically used in wastewater treatment. This means lower operating costs and a smaller environmental footprint. Furthermore, the process is highly energy-efficient. It requires less energy compared to conventional treatment methods. This translates into significant cost savings and reduced carbon emissions.

LOADING...

LOADING...

DATE:2024年07月30日

DATE:2024年07月30日